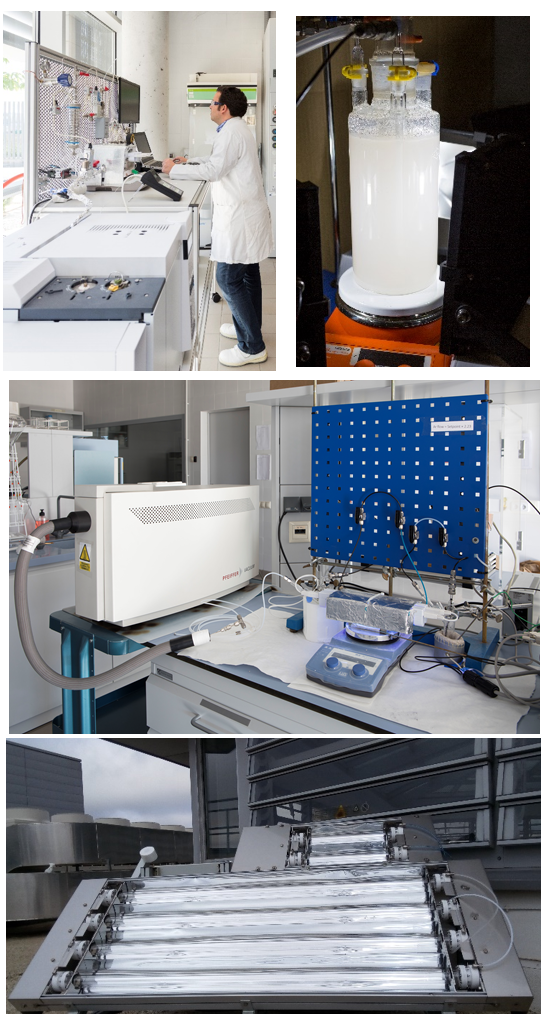

CO2 conversion reactors: 2 continuous-flow mode stainless-steel reactors with borosilicate windows for irradiation. UV illumination is provided by four 6 W fluorescent lamps with a maximum wavelength at 365 nm, and visible light irradiation by a 30 W LED white lamp emitting from ca. 400–800 nm, with maxima at 445 and 540 nm. The system is equipped with mass flow meters for Ar, CO2 and water with a Controlled Evaporation and Mixing (CEM) unit. The products of the reaction are determined in-line by gas chromatographs equipped with two separation branches and two sampling loops. The first separation branch is equipped with two semicapillary columns (BR-Q Plot and BR-Molesieve5A), a thermal conductivity detector (TCD), a flame ionization detector (FID) and a methanizer. The second separation branch consists of a capillary column (CP-Sil5B) and an FID.

CO2 Liquid-phase water splitting / ammonia synthesis reactors:

1 L and 130 mL Pyrex glass reactors incorporating a water-cooled immersion lamp, either 125 W low-pressure mercury for UV or 150 W Xe arc for UV-visible light. The system is provided with a mangetic stirrer and connected to argon and nitrogen lines. In-line analysis of the outlet gas is performed with a dual-channel micro-GC 490 from Agilent Technologies, equipped with MS5A PLOT and PoraPLOT U columns and TCD detectors.

Gas-phase water splitting reactor: Continuous-flow mode stainless steel reactor of 10.8 cm3 volume, provided with a borosilicate glass window for external irradiation by 2 fluorescent UV lamps of 6 W each (λmax=365 nm), or by a 30 W LED white lamp emitting from ca. 400–800 nm, with maxima at 445 and 540 nm. The reactor is fed by an Ar flow that passes through a thermostated bubbler for sacrificial agent feeding. Hydrogen evolution is monitored by in-line mass spectrometry.

Solar reactor: This fully automatized solar reactor has been specifically designed for gas-phase photocatalytic and photoelectrochemical reactions (water splitting, photoreforming, CO2 reduction, N2 fixation) and for the specific location of the IMDEA Energy Institute. Solar radiation is collected wiht compound parabolic collectors (CPC) of anodized aluminium with two differtn collecting areas of 0.9 and 0.12 m2, depending on the scale of the experiment to be carried out. Lamps can be included in each of the tubes for day-night operation.

The equipment consists of six parallel annular tubular borosilicate glass reactors than can be connected in series or used independently. The system is conceived for gas-phase continuous mode reactions and includes a rack micro-GC with MS5A PLOT and CP-Wax 52 CB columns and a radiometer.

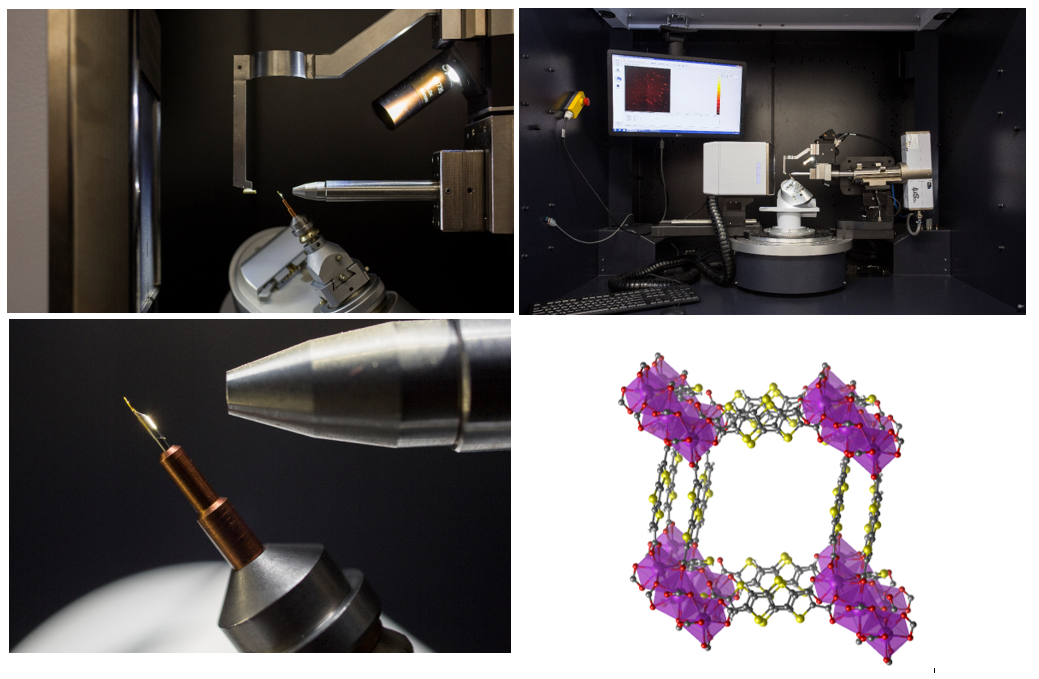

Bruker D8 Venture Diffractometer is a 3D single crystal structural determination system. The system covers all the characteristic applications of a single crystal in organic and inorganic chemistry, solid state chemistry and organometallic. It features a high brightness copper X-ray micro-source (Cu Kα radiation, λ = 1.54178 Å), a PHOTON100 detector with CPAD technology for X-ray diffraction imaging. It has a goniometric system with Kappa geometry for the site of the sample (which allows total freedom of positioning of the sample).

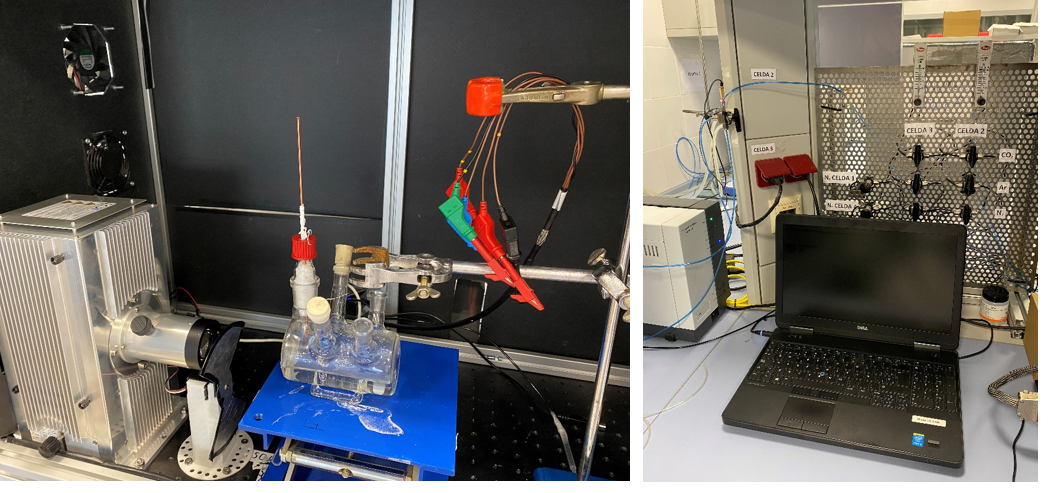

Photoelectrochemical measurements are performed in different electrochemical cells, coupled to a potentiostat: Autolab Multi PGSTATM204, Autolab PGSTAT204 equipped with a FRAII module(10 mV of modulation amplitude is used at 400 Hz) and a Dropsens µStat400. Light irradiation are performed using one of the two solar simulators LSH302 Xe lamp with an LSZ389 AM1.5 global filter. Additionally, the photoelectrochemical set-up can be coupled with an microGC (Agilent) in to quantify the generated products from the photoelectrochemical reactions.

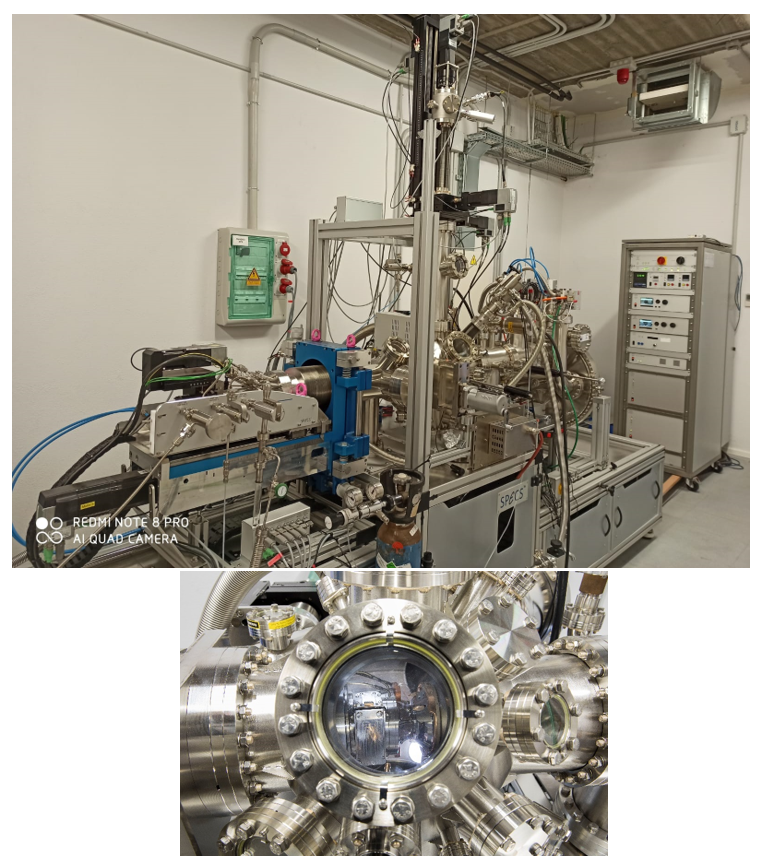

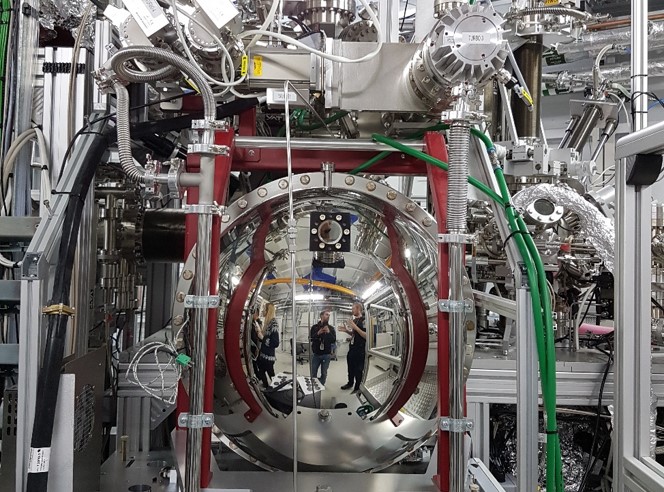

The NAP-XPS facility at IMDEA Energy (SPECS Surface Nano Analysis, GmbH Germany) is equipped with a monochromatic Al Kα X-ray source of high intensity, and a PHOIBOS 150 Hemispherical Energy analyser coupled with a differentially pumped electrostatic pre-lens system. The NAP studies are done in a reaction cell installed via a chamber-in-chamber design inside the analysis chamber. Whilst the analysis chamber remains at base pressure around 10-9 mbar, the reaction cell can reach up to 20 mbar, and temperatures ranging from -200K to 1000K. UHV sample preparation is possible with an Ar+ sputter gun and an e-beam heater. The system also includes a He-UV source for UPS studies.

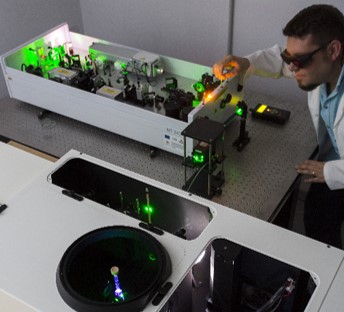

The laser flash photolysis equipment. Transient Absorption Spectra equipment (LP980-K) purchase by Edinburgh Co, has a Nd:YAG laser (EKSPLA) with four harmonics and equiped wiht an optical parametric oscillator (OPO) and with an UV extension. The wavelength can be set from 210 nm to 2600 nm, with a pulse width of about 5 ns. A pulsed xenon flash lamp (150 W) is employed as detecting light source. A monochormator (TMS302-A, grating 150 lines/mm) disperses the probe light after it has passed the sample. The equipment is also provied wiht several detecters: ICCD Camera, PMT and InGaS that cover a wide rante of the spectrum. Several holders can be adapted to measure liquids, solids and thin films.

Time-Resolved Fluorescence. The Mini-tau (Edinburgh Instruments) allo measuere lifetimes ranging from 25 ps to 50 μs. EPL-375 picosecond pulsed diode laser with emission at 372 or 445 is used as source excitation. Liquid and solid powdered samples can be monitored.

Materials characterisation

We use an array of laboratory techniques in order to characterise the new materials synthesised and their chemical (ICP-OES, EA, NMR, FTIR, Raman, MS), structural (XRD, TEM) and morphological (SEM, nitrogen adsorption-desorption isotherms) composition and electronic properties (UV-Vis spectroscopy, EIS, photovoltages, UPS).

Mechanistic studies

We use a range of laboratory and synchrotron in-situ and operando techniques such as FTIR, Raman, XRD, XPS and XAS to probe the electronic state of the main actors involved in the photocatalytic process at operando conditions. These experiments allow us to monitor the oxidation state of the catalyst and to identify reaction intermediates and products at its surface under UV-irradiation and CO2/H2O atmosphere.